This year marks the 60th anniversary of laser technology. In the years since its launch, lasering has grown into a global industry touching an enormous range of industrial processes and consumer products. From the coding of everyday items such as beverage cans, to the batch marking of printed circuit boards and the intricate cutting of packaging, lasers make a positive contribution to how we all live and work.

For example, it is now possible for the laser coding of beverage cans to run at line speeds of 125,000 units per hour.

This offers significant productivity gains, particularly for 24/7 operations, but at the same time also presents new challenges in capturing the potentially harmful airborne contaminants that can be emitted as a result of this process.

Higher line speeds mean greater potential dispersal of particulate, including nanoparticles, both at the laser source and over extended areas of the production line as a result of ambient airflow entrainment created by the high-speed process.

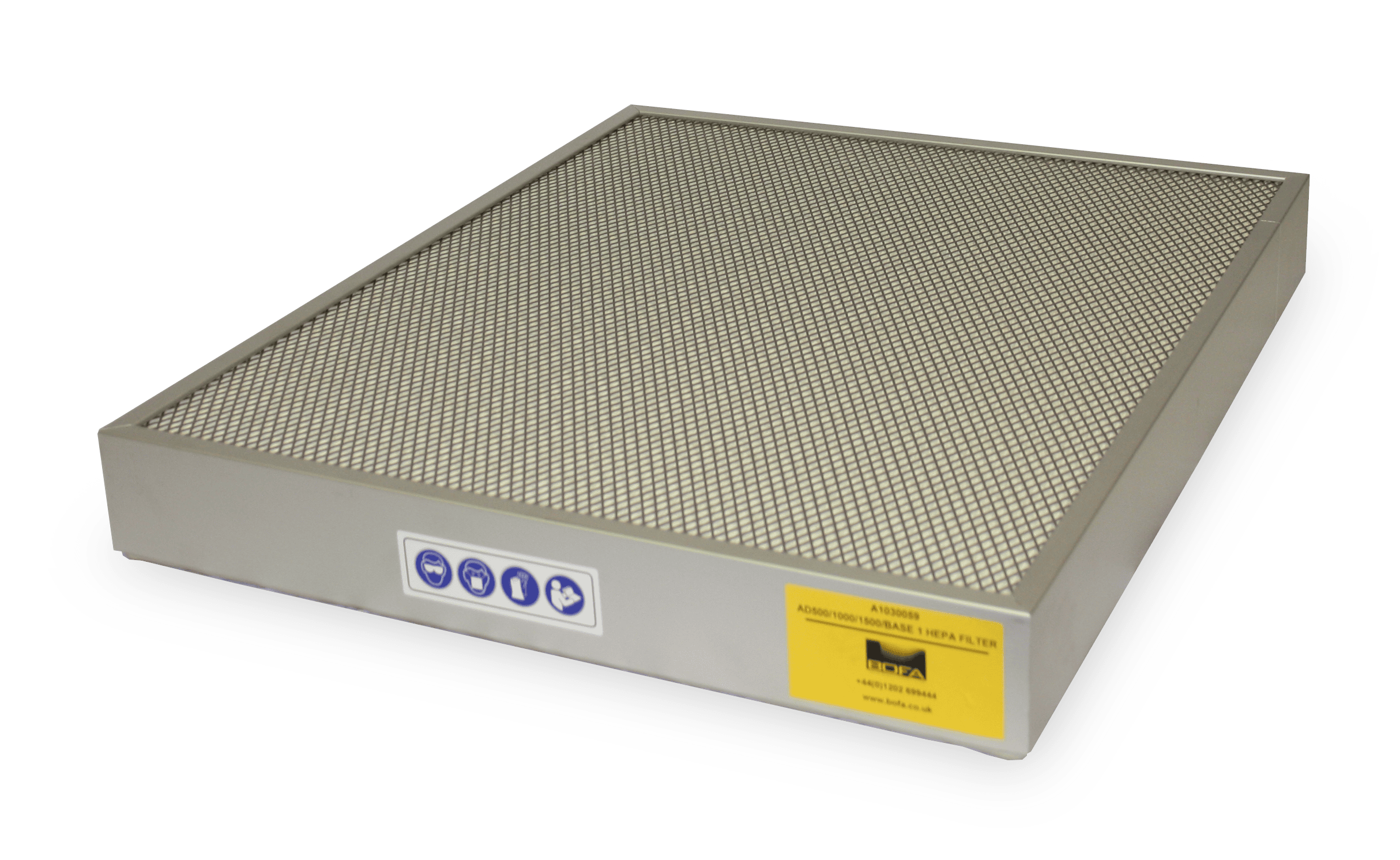

It has long been recognised that particulate emitted by cutting and ablation can create adverse health reactions in people, such as occupational asthma, and indeed the laser cutting of certain materials, such as PVC, can generate highly toxic fumes and acids. As a result, advanced extraction systems, such as those developed by BOFA, are seen as fundamental to removing particulate and ensuring a safe working environment. This includes capturing nanoparticles measuring between 1 and 100 nanometres in diameter (i.e. up to 0.1 micron), which are invisible to the naked eye and can pass through the body’s natural defence systems. Nanoparticles like these have the potential to be ingested into the lungs with the further potential to enter the blood stream. The highly efficient HEPA filters in BOFA extractors and dust collectors are designed to safely and efficiently capture these microscopic particles, allowing clean and filtered air to be returned to the atmosphere.

Capturing these fumes and particulate is key to the safe operation of all lasers, but particularly those operating at higher speeds, because of the risk of disparate particulate spread and worker exposure.

BOFA has extensive in-house engineering and scientific expertise to help manage these risks by offering designs utilising innovative system geometry and optimised airflow, coupled with multi-stage filtration. This architecture is a key enabler in delivering the productivity benefits associated with faster operations while at the same time safeguarding laser resolution and accuracy by keeping lines free from contamination.

Geoff Sagar, Business Development Manager for Laser Systems at BOFA commented:

The flexibility of our systems – and our wide range of product architectures – makes them perfectly suited to high speed environments where particulate momentum makes fume and dust capture more complex and challenging.

However, our engineers and technicians are experts in modelling the potential airborne contaminant spread of each process and can then advise on the necessary system elements and optimal positioning of our portable technology to contribute to compliant health protection while helping deliver contaminant-free process lines.

Laser technology has certainly moved on apace since 1960, both in terms of higher speeds and greater coding, marking and cutting accuracy. The technology driving higher speeds can increase operating temperatures in some processes, and while the risk is small, BOFA has developed technologies to help mitigate the potential for adverse thermal events to protect operations that can run 24/7 all year round.

For these applications, BOFA systems can incorporate fire-resistant casings and filters and triple thermal cut-out protection, along with spark arrestors and fire boxes (with inline extinguishers) to manage risks associated with incandescent particulate transported in fast moving operations.