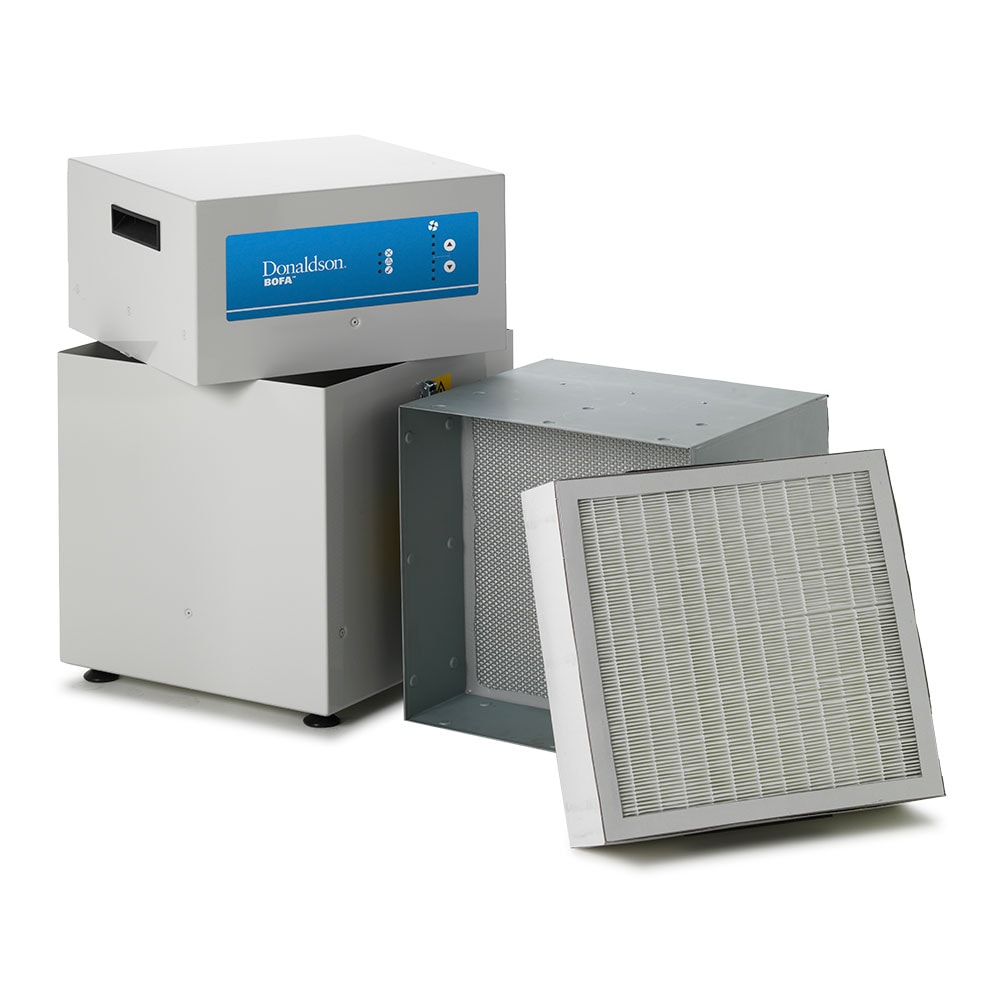

V 600

The V 600 fume extraction system is designed to filter fume from soldering and various electronics applications. It features a long-lasting filter, high airflow rates, and the capacity to support up to seven operators.

- Long-life, low-cost replacement filters

- High airflow rates

- Built-in silencing

This system is also available as part of the Shield & V 600 bundle.

Approvals: UKCA and CE

Features

DeepPleat pre-filter

The DeepPleat pre-filter consists of a pleated filter allowing for increased surface area within a smaller volume. This means Donaldson BOFA filters last for a long time and do not take up a large footprint.

HEPA filter

Our HEPA filters are rated to filter 99.995% of particles at 0.3 microns. A secondary filter to remove fine particulate.

Advanced carbon filters

Our advanced carbon filters help to capture contaminants and odors, reducing the risk of bypass and tunneling. They are designed with specific carbon types tailored to industry applications.

Reverse flow air technology

Our reverse flow air technology reduces velocity and changes air direction, causing larger particulate to fall into the filter’s drop-out chamber. This decreases particulate entering the filter media, significantly enhancing filter capture performance, and extending filter life.

Multi-voltage sensing

Automatically senses the local voltage and adjusts accordingly.

System OK signal (optional)

Our system OK signal alerts you when there is a fault, and when filters are blocked, allowing you to schedule maintenance efficiently.

Remote stop/start signal (optional)

Our remote stop/start signal ensures that your Donaldson BOFA fume extraction system operates only when your machine is running, helping to save on both running costs and energy.

VOC sensor (optional)

Our VOC (volatile organic compound) sensor continuously monitors exhaust air and alerts you if VOC levels exceed the pre-set threshold, preventing the unwanted release of VOCs and other nuisance odors.

Technical specification

| Imperial | Metric | |

|---|---|---|

| Dimensions (HxWxD) | 23.23 x 14.76 x 18.31” | 590 x 375 x 465 mm |

| Weight | 77 lbs | 35 kg |

| Airflow / Pressure | 206 cfm / 96 mbar | 350 m³/hr / 96 mbar |

| Electrical data | 115-230 V 1 ph 50/60 Hz Full load current: 12.5 amps / 1.1 kw | 115-230 V 1 ph 50/60 Hz Full load current: 12.5 amps / 1.1 kw |

| Noise level (at typical operating speed) | < 60 dBA | < 60 dBA |

| Cabinet construction | Powder-coated mild steel | Powder-coated mild steel |

Documentation

Product Inquiry

For more information about this product, please get in touch. Simply fill out the form, specify the system you’re interested in, and a member of the team will get back to you.

Filter Technology

We offer a variety of pre, main, and inline filters designed to effectively capture dust and particulate generated across a wide range of applications.

Smart Technology

At Donaldson BOFA, we have developed innovative technologies to help you manage your extraction systems effortlessly, reduce downtime, and enhance overall productivity.

SureCHECK

We uphold our quality standard through our unique SureCHECK process. We conduct rigorous testing and inspections on every product we make to ensure product integrity, reliability, and performance.

Contact Us

We’re here when you need us, with a variety of ways to get in touch.