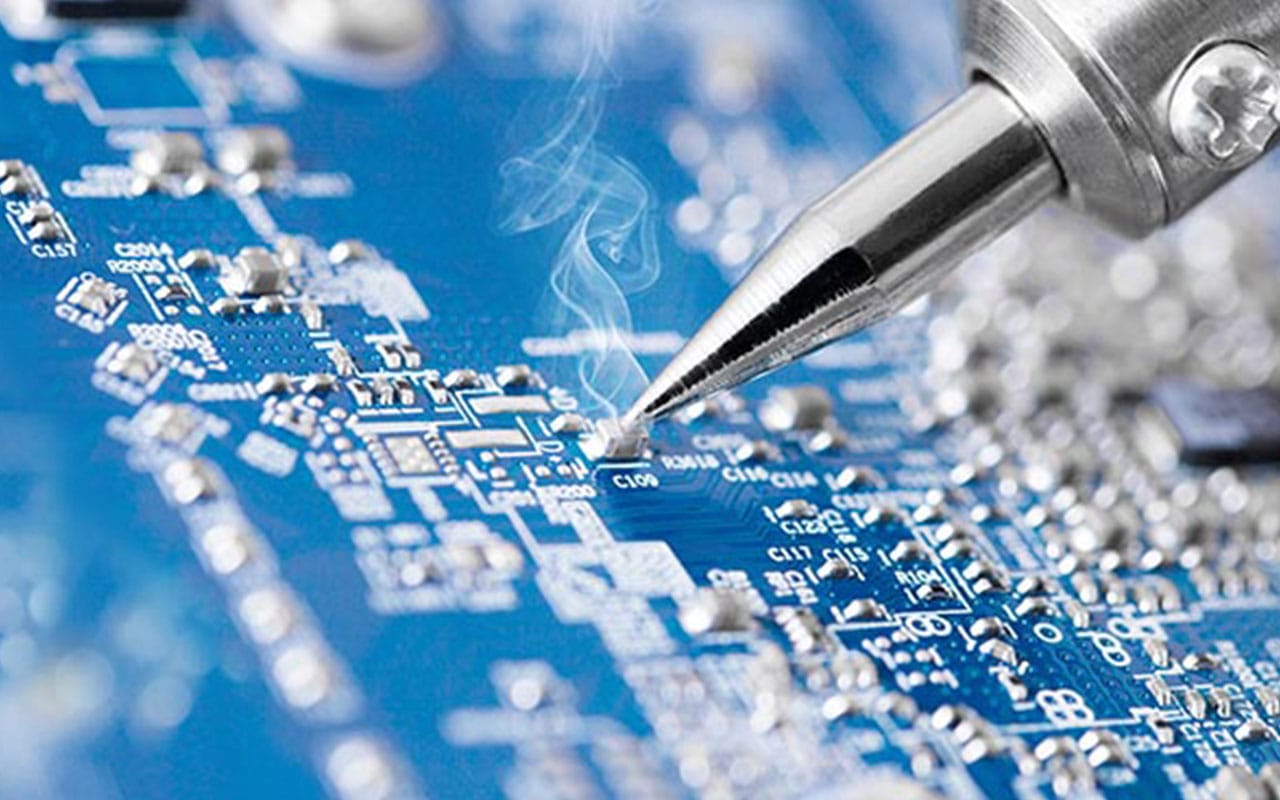

Amid the high-tech wizardry of today’s advanced electronics, it may come as something of a surprise to learn that process operating temperatures play a vital role in product quality and PCB assembly.

That’s because there is a direct link between temperature and the solder paste efficacy that supports the placement of surface mount devices during PCB assembly. Indeed, ineffective temperature control within the PCB print process is thought to be one of the most common causes of production problems, which can result in defects, reworking, downtime… and significant costs to businesses, particularly in 24/7 operations.

This stark realisation of the need to maintain print area temperatures within the tolerances of solder paste specification has grown in step with the globalisation of PCB assembly operations, and the establishment of production facilities in countries and regions subject to extremes of temperature and humidity, which can impact process temperature. A lack of focus on this critical process parameter is thought to be responsible for many assembly defects, with the trend towards miniaturisation making adherence to tolerances even more mission critical.

BOFA’s portable fume extraction technology is routinely specified in many electronics manufacturing processes to help ensure the removal of potentially harmful airborne contaminants from reflow, wave soldering and conformal coating systems. But the company’s electronics industry insight and its application knowledge have also led to the development of a temperature control unit (TCU) that can help safeguard the optimal operating conditions for PCB productivity.

BOFA’s TCU is designed specifically to help maintain PCB print area temperatures within a programmable 19 – 30oC parameter and is accurate to within 1ºC thanks to integrated sensor-driven heaters and refrigerated cooling. An air filtration system helps to prevent process contamination, while any condensate produced is gravity-fed to a 5-litre container or piped to an external drain. Two capacitive level sensors monitor the condensate level.

The unit can be used with a wide range of solder paste printers providing hoses can be connected to recirculate the air between the printer and the TCU.

This is technology that helps maintain the desired process temperature tolerances in surface mount applications and helps negate the risk of increased solder paste viscosity that can result from lower than specified temperatures, which in turn can lead to poor stencil release and joint defects.

Should the process temperature be too high, paste viscosity decreases, risking smearing, with the potential for component oxidisation and compromised solderability.

Integrating BOFA’s TCU helps PCB manufacturers regulate the temperature in the print area and helps to reduce the potential for defects. As such, it presents a strong return on investment proposition given the potentially significant costs associated with unplanned downtime, rework and delayed customer deliveries.

Find out more about our TCU here.