Why is Fume and Dust Extraction Needed?

Fume and dust extraction technology plays an important role in helping companies both manage workplace environments and improve productivity.

Portable systems developed by Donaldson BOFA help to filter potentially harmful airborne emissions that can result from certain processes and applications, including laser, electronics, printing, additive manufacturing, and 3D printing.

Airborne contaminants can include both particles (including nanoparticles) and gases (including volatile organic compounds). Fume filtration technology can help employers implement their workplace environment health strategies. A correctly installed and maintained filtration system can also make a positive contribution to productivity by filtering dust and particulate that might otherwise contaminate equipment and potentially lead to downtime.

Airborne contaminants can include both particles (including nanoparticles) and gases (including volatile organic compounds). Fume filtration technology can help employers implement their workplace environment health strategies. A correctly installed and maintained filtration system can also make a positive contribution to productivity by filtering dust and particulate that might otherwise contaminate equipment and potentially lead to downtime.

The first step in assessing risk is to make reference to the material’s Safety Data Sheet to understand the nature of any emissions associated with any given process, while also checking the local regulations governing any workplace exposure levels.

At Donaldson BOFA, we have considerable experience working with industries to find the most appropriate filtration solution for given processes. We can help identify the type, volume, size, shape, and velocity of particles being emitted and provide filtration system options for managers to consider.

How does Donaldson BOFA Technology help Workplace Environments?

Donaldson BOFA’s fume and dust filtration technology helps to filter airborne contaminants emitted across a range of industrial processes. And because Donaldson BOFA equipment is portable, it can support an agile manufacturing environment.

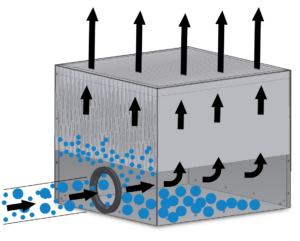

Donaldson BOFA systems incorporate a suction pump that draws airborne emissions into advanced filtration technology. These filtration systems include patented DeepPleat DUO pre-filtration, a main HEPA filter, and a layer of activated carbon to filter vapors and gases. The exact configuration, airflow rates, and filtration media will depend upon each application and the industrial process involved.

What are the Core Functions of the Key Components?

DeepPleat DUO pre-filter technology incorporates a large capacity drop-out chamber to filter high volumes and a variety of particulate in advance of the main HEPA filter. This system helps optimize the life of the HEPA filter.

Airflow is also an important element in extraction performance. Donaldson BOFA’s automatic flow control feature allows operators to pre-set airflow rates for specific applications, helping to optimize HEPA filter lifecycles.

Reverse flow air technology can also contribute to filter performance. It facilitates a fall in velocity and an air direction change, meaning larger particulate falls out of the airstream into the drop-out chamber. With less particulate entering the filter media, the filter life is optimized.

Does the Filtration System Vary According to Application?

Donaldson BOFA systems are designed to deal with process-specific emissions, including laser cutting, laser coding, electronics soldering, ink jet coding, and 3D printing. Each solution takes account of the processes, substrates, and chemical interaction.

Find an Extraction System for Your Process

Whatever your application, there’s a fume extractor to suit your needs. Contact us to discuss your requirements and find out which systems best suit your process.