Every day, around the world, Donaldson BOFA’s fume and dust extraction technology is helping companies to manage the safety of their workplace environments and improve productivity.

Whether it’s additive manufacturing, lasering, electronics production, printing, or another fume-emitting process, our portable systems are filtering potentially harmful airborne particles.

Developing Fume Extraction Systems to Meet Your Requirements

Our engineers are experts in identifying the composition, volume, size, shape, and velocity of emissions and developing a filtration system matched to end user requirements.

As Josh Evans, Applications Engineer at Donaldson BOFA explains: “Our filtration technology helps to reduce exposure to unwanted substances in the workplace. At the same time, our systems help keep production equipment free from dust that might otherwise impact on product quality. And because our technology is portable, it can support an agile manufacturing environment.”

Donaldson BOFA’s systems typically comprise a 3-stage filtration architecture, which when coupled with advanced air flow control, provides high levels of extraction performance while optimising filter life and helping to lower the overall cost of ownership.

The 1-2-3 of Donaldson BOFA’s Filtration Technology

- Stage 1: The pre-filter, such as our patented DeepPleat DUO, incorporates a large capacity drop-out chamber to collect high volume of larger particulate. This helps capture the bulk of emissions, thereby optimising the life of the HEPA (High Efficiency Particulate Air) filter.

- Stage 2: The HEPA filter is purpose-designed to create a large surface area capable of capturing 99.995% of particles at 0.3 microns. This helps to protect operatives from airborne contaminants with potential to be harmful to human health.

- Stage 3: A layer of activated carbon removes vapours and gases such as VOCs (volatile organic compounds), specially formulated to handle specific chemical interactions.

The exact configuration, airflow rates and filtration media will depend upon each application and the industrial process involved.

Configuring Our Systems Depending on the Application

Take a laser process compared to electronics production, for example. The HEPA and carbon filters will be the same for both processes, but the pre-filter will need to filter large amounts of fume in laser processing. By comparison, pre-filtration for electronics production will require a smaller capacity.

In printing, some wide-format printers use a solvent called butanone, also known as methyl ethyl ketone (MEK). This can react exothermically with untreated carbon. So here, specially treated carbon would need to be used.

In mechanical industries, such as sanding and drilling, no gases are given off, so no activated carbon filter is required. For this reason, dust extractors such as Donaldson BOFA’s DustPRO range are specified as a 2-stage system, with a pre-filter and HEPA filter.

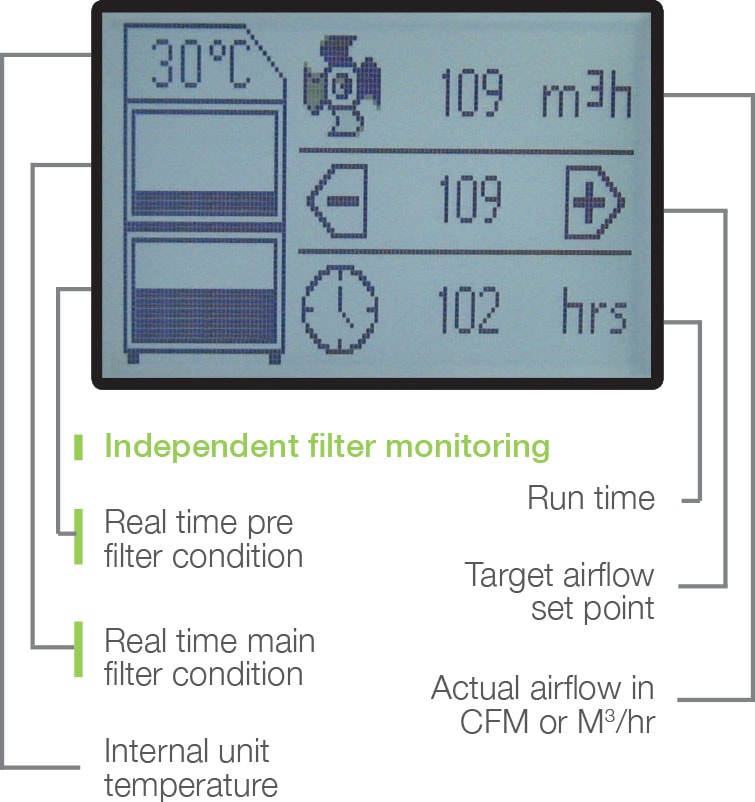

Another critical factor is system control. Donaldson BOFA’s Intelligent Operating System (iQ) will respond dynamically as filters begin to fill to maintain the airflow needed to deliver the specified extraction performance. iQ provides a visual system condition read-out, along with independent filter status monitoring to enable operators both to order replacement filters and exchange them in a timely fashion to avoid the risk of unplanned downtime.

To find out more about Donaldson BOFA’s filtration systems, get in touch with our knowledgable team today.