At BOFA, we want everyone to go home healthy, and with the increasing role of technology in education, this means doing what we can to raise awareness in schools, colleges and universities of the dangers presented by airborne contaminants.

In tertiary education, extraction systems are used extensively to remove potentially harmful fume and dust associated with laser technology, chemical experimentation, 3D printing, woodwork, and electronics – and we partner with many institutions to ensure effective extraction and filtration is in place.

We make sure to carefully run through exactly what is required, so that accurate consideration is made when selecting the extraction system and any accessories. During this exercise, we will involve BOFA experts from our technical, applications and product management teams, making sure that our customers are getting the best extraction systems to suit their needs.

Legislation is in place in many countries, to make sure exposure to such harmful substances is prevented, and to ensure that equipment installed in the workplace is performing correctly. In Europe, the EU issues guidelines but most countries have their own occupational exposure limits (OELs). In the UK, the Health and Safety Executive is the legislative body, and the requirements are covered by the Control of Substances Hazardous to Health (COSHH) Regulations whilst the exposure limits are set out in the HSE booklet EH40.

Our experience is that some establishments meet these standards to the letter – others do not, mainly through a lack of knowledge. For example, we have found good extraction systems rendered ineffective by blocked filters; seen unfiltered fumes vented through a wall next to a drinking fountain; and ‘vent-to-air’ systems – which are meant to vent above roof height – dispensing fumes at window level.

Here we have some bite-sized revision about the potential risks associated within different fields….

Laser risks:

In laser activities, various chemical vapours, aerosols or fumes can be emitted, depending on the material being worked. The very fine particulate resulting from laser cutting or marking wood, ply, paper and mdf, for example, is micron and sub-micron in size and highly respirable.

The lasering of acrylic emits methyl methacrylate vapour and can result in sensitisation or allergic reaction, leading to contact dermatitis or occupational asthma. This chemical has an 8 hour TWA exposure limit of 208 mg/m³.

BOFA’s ADVANTAGE range of fume extraction and filtration systems are designed for applications that generate particulate and gaseous volatile organic compounds within laser industries. To find out more, please contact us here.

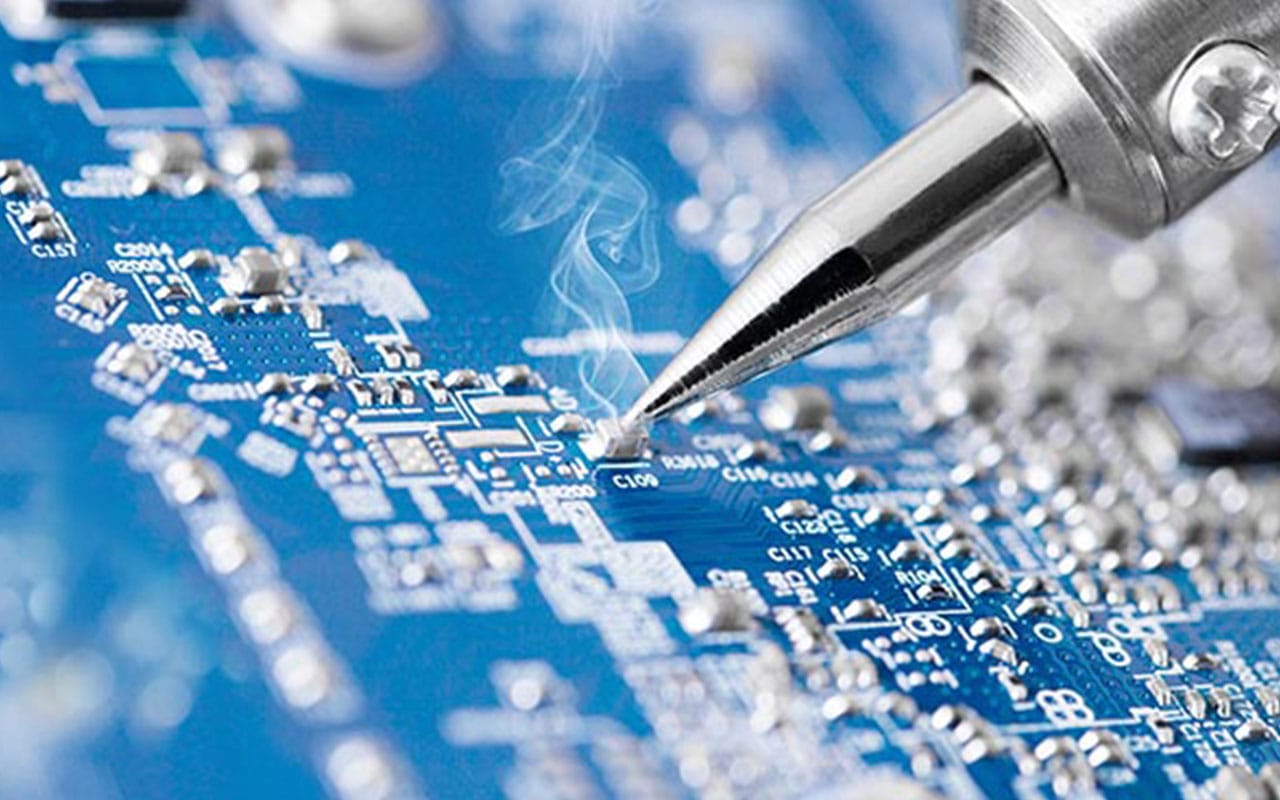

Soldering risks:

Inhalation of solder fumes will cause irritation to nose, throat, and respiratory organs, and any extended or repeated exposure can cause hypersensitivity and lead to occupational asthma (see HSE, INDG248). The exposure limits for rosin-based solder flux fume are an 8-hour TWA of 0.05 mg/m³, and a 15-minute TWA of 0.15 mg/m³. It is an expectation that contaminant levels are reduced as far as reasonably practicable below the exposure limit.

BOFA’s range of Tip, Volume and FumeCAB systems are cost effective solutions for helping keep the user’s breathing zone clear of potential harmful airborne contaminants. To find out more, please contact us here.

3D Printing risks:

With many 3D printers, the risk arises through the release of volatile organic compounds and ultra-fine nanoparticles, which are too small for the human eye to see but which should also be captured. Inhalation of these pollutants can cause risk to health (see HSE, RR1146 “Measuring and controlling emissions from polymer filament desktop 3D printers”).

BOFA’s 3D PrintPRO range provides effective fume extraction and filtration rates in compact units, with optional speed control, to maintain cleaner print area and returns filtered air to operator breathing zones. To find out more, please contact us here.

Woodwork:

Woodwork of course is also a subject undertaken in higher education. Sawing, routing, milling and particularly sanding processes are known to generate inhalable dust, with the potential to create lung disease and breathing problems unless appropriate extraction systems are in place.

With such a variety of wood processes, it’s sometimes difficult to figure out which fume extraction system is best for you. Contact our BOFA experts, and they will be happy to discuss the most effective extraction and filtration system to suit your needs.

As students are now returning to education in an era of heightened awareness about the need to look after air we breathe, find out more here about our range of extraction systems that have been designed to protect you, and others around you.