How can I extend filter life?

This is one of the most frequent questions posed to the Donaldson BOFA help desk. There is no uniform answer because the point at which filters need to be exchanged will be determined by the process involved. The volume and composition of the fume can vary significantly but the good news is Donaldson BOFA tailors each extraction system to match the process and completes a rigorous quality check to make sure that each system is set up correctly before dispatch. It’s also worth monitoring filter lifecycle, so that you know if something is out of kilter if you find filters are becoming saturated more quickly.

What do I do if I notice a change in filter life?

If this happens, the first check should be focused on the process. Has something changed…are different materials being worked? This can impact both the volume and composition of emissions and can potentially saturate filters more quickly. So best to contact Donaldson BOFA’s technical team if you are considering a process change.

What can I do to optimize the performance of my filters?

Regular inspection and simple maintenance will help keep units in optimal condition by keeping inlets and outlets free from debris. Systems should never be run with a blocked filter or obstructed inlets/outlets. Take a look at the user manual that came with your Donaldson BOFA system because this contains useful hints and tips for maximizing filter life, cleaning the system, and replacing filters.

How do I know when the filter exchange point is approaching?

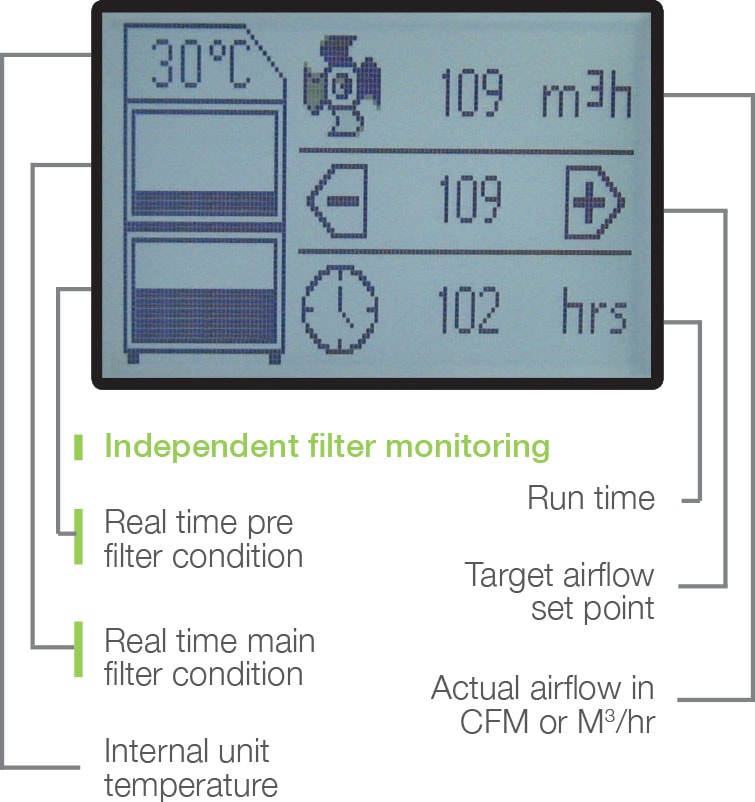

We make it as easy as possible for operators to view their extraction system performance in real time, particularly for those systems featuring the Intelligent Operating system (iQ).

The visual read-outs show operating information covering temperature, blower status, airflow rates (actual vs target set point), and filter condition. This makes monitoring filter saturation levels simple and helps users schedule filter exchanges in step with maintenance plans. And because iQ stores downloadable historical performance data, it is easy to see the impact on filter lifecycles of changes to production and maintenance regimes.

How can I find out more?

You can find out more about optimizing filter life by contacting Donaldson BOFA’s technical team.